Investing in a vacuum pump is an important decision for any operation, and selecting the right one is crucial to ensuring the application needs are fully met and longevity of pump operation. At FluidX, we understand the importance of making an informed choice. Here’s a guide to help you navigate the key factors to consider when selecting a vacuum pump for your application.

Define Your Application

The first step in choosing the right vacuum pump is to clearly define your application. Understanding the specifics of what you expect from your vacuum pump will guide you in determining the most suitable type for your needs. Consider the following questions:

- What is the purpose of the vacuum pump in your process?

- Are you dealing with a continuous gas load or intermittent usage?

- Do you need to evacuate a vacuum chamber, and if so, how quickly?

By answering these questions, you can narrow down your options to find a pump that meets your operational requirements.

Key Factors to Consider

1. Flow Rate

The flow rate, measured in cubic feet per minute (CFM), is critical if your vacuum pump will be handling a continuous gas load or if you need to achieve a specific vacuum level within a timeframe. Ensure that the flow rate matches the size and demands of your system to maintain efficiency and effectiveness.

2. Vacuum Level (Ultimate Vacuum)

Understanding the required vacuum level for your application is essential. Vacuum levels are categorized as:

- Rough vacuum: From 1000 mbar to 1 mbar

- Medium vacuum: 1 mbar to 10^-3 mbar

- High vacuum: 10^-3 mbar to 10^-7mbar

- Ultra-high vacuum: 10^-7 mbar to 10^-12 mbar

Identify the vacuum level your process requires to select a pump capable of achieving and maintaining that level.

3. Process Cleanliness

Consider the cleanliness of your process. Some vacuum processes involve contaminants such as particles, water vapor, or chemicals. Choose a vacuum pump that can handle these contaminants without compromising performance or longevity. Additionally, consider using filters or traps to remove contaminants before they reach the pump.

Common Types of Vacuum Pumps

Understanding the different types of vacuum pumps and their applications can also aid in your decision:

- Liquid Ring: Excellent for wet or dirty processes, offering a robust and reliable solution.

- Single Stage Oil-Sealed Rotary Vane: Ideal for a variety of applications but requires regular maintenance due to oil changes.

- Dry Rotary Vane: Suitable for applications requiring a clean vacuum environment without oil contamination.

- Two Stage Oil-Sealed Rotary Vane: Ideal for a variety of instrumentation and laboratory applications but requires regular maintenance due to oil changes.

- Dry Scroll: Provides a clean and oil-free vacuum in laboratory environments.

- Multi-Stage Roots: A dry pump that delivers high pumping speeds at low pressures, suitable for laboratory as well as demanding semiconductor applications.

- Turbomolecular: Best for achieving high and ultra-high vacuum levels, often used in scientific and research applications. Requires a backing vacuum pump.

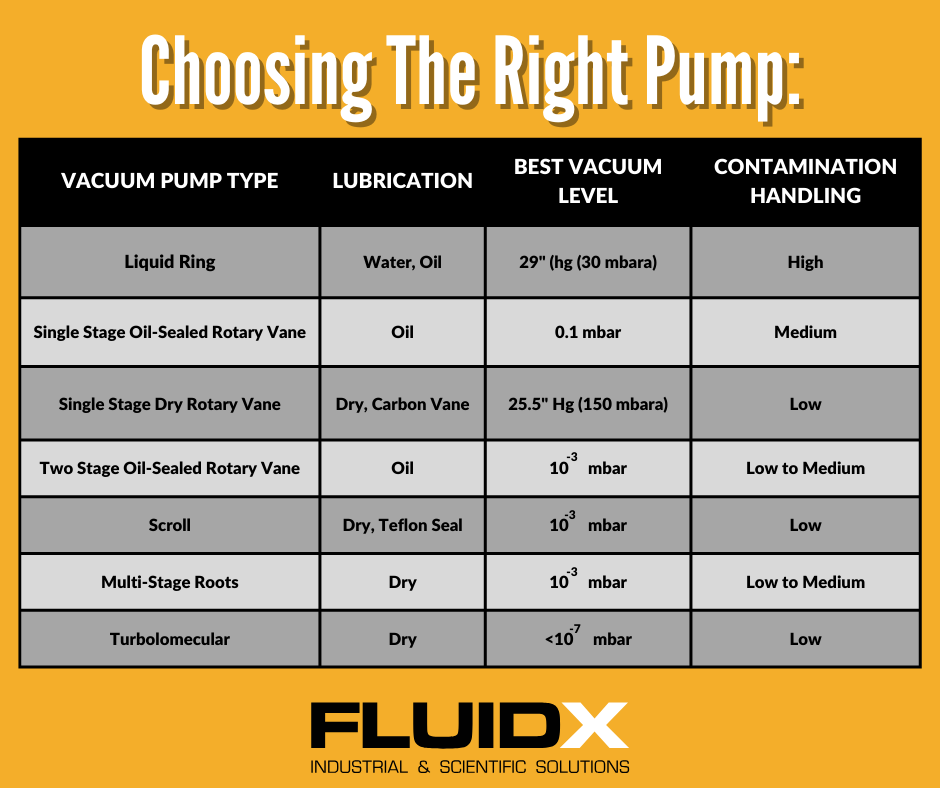

Need help deciding on the pump you need? Use this table to help you choose the right pump:

Need Help? Contact FluidX

Selecting the right vacuum pump can be complex, but you don’t have to do it alone. FluidX Applications Specialists are here to help you navigate through the options and find the best vacuum pump for your specific needs. At FluidX, we’re committed to helping you make the best choice for your operation, contact us today for expert assistance and support.